Climate journey

We are committed to operating more sustainably by continuously working to measure and reduce our carbon footprint at every stage of our bottle life cycle from the materials we use, to production, bottling, transportation and recycling.

Our actions

Transport

We are continuously optimizing to lessen our environmental impact by increasing efficiency whenever possible. For example, knowing that train transportation carbon footprint is 10x smaller than trucks in France, we transport about 90% of our bottles from our factory to our warehouses by train. Another initiative is that our logistics team is equipped with a carbon calculator to help incorporate carbon impact into decision making.

Packaging

Considering Packaging & End of life, recycled PET has a 30% lower carbon emissions compared to virgin PET (15% when considering product full life cycle). In complement to advocate for a circular model, evian aims to use only rPET to produce its bottles by 2025. Currently, we have an average of 87% rPET* YTD Sept 2025 across our range of bottles. To learn more go to Package and recycling.

*excludes label and cap

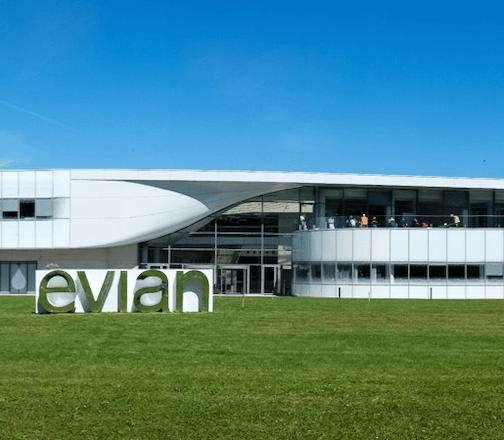

What makes our bottling site so unique? It runs on 100% returnable energy generated from hydropower and biogas:

Hydropower is electrical energy (hydroelectricity) that is produced by using water to move turbines that power a generator to produce electricity.

Biogas is composed of methane produced by the breakdown of organic matter, such as agricultural waste, manure, plant material, sewage, green waste or food waste.

Production

- Our factory is more than a place for bottling water, it’s also tasked with sustaining a long-term future for the circular economy. This future is being constructed at our factory, the place where all of our products and innovations were created, and where tomorrow’s will be developed to meet its economic, social, and environmental challenges going forward.

- Our bottle site is an example of best-in-class energy and environment management systems. Between 2009 and 2024, the energy consumption per bottle decrease by 30%. This reduction has been enabled by several projects, managed by a dedicated team working on a daily basis to monitor andcontinuouslyimprove energy consumptions.

How to reduce our plant consumptions:

- ISO 50001 certified since 2015

- implementation of a new efficient production process

- staff training on energy, waste and water consumption reduction, carbon footprint

- regular reports of energy consumption and optimization

Our bottling site is also entirely powered by renewable energy.